The Pinnacle of Precision: Exploring the Best Carbide Planer Inserts for Superior Woodworking

In the realm of woodworking, the quality and efficiency of cutting tools significantly impact the final product. Among these tools, carbide planer inserts have risen to prominence as essential components that deliver exceptional performance and durability. Their advanced design and material composition make them indispensable for achieving precision and consistency in woodworking projects.

Carbide planer inserts are crafted from carbide - a robust, high-density material composed primarily of tungsten carbide particles bonded with cobalt. This composition gives the inserts their characteristic hardness and resistance to wear, making them ideal for the demanding tasks of planing wood. Unlike traditional high-speed steel blades, carbide planer inserts maintain their sharpness longer and withstand the stresses of high-speed operations, resulting in cleaner cuts and reduced maintenance.

One of the key advantages of carbide planer inserts is their ability to handle various types of wood, from soft pine to dense hardwoods. The inserts are engineered to cut through these materials with ease, delivering smooth, even surfaces without the frequent chipping or dulling that often accompanies less durable blades. This versatility is crucial for professionals who require reliable performance across a range of wood species and applications.

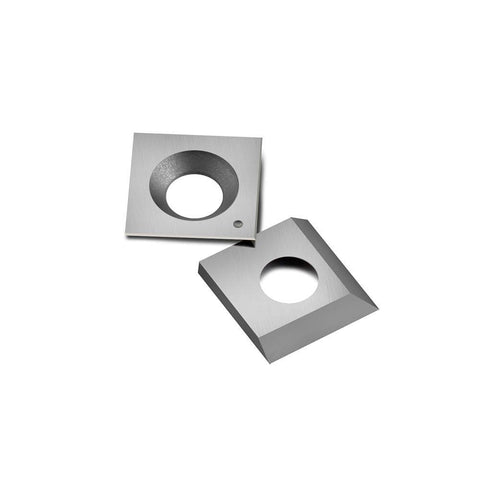

The design of carbide planer inserts contributes significantly to their effectiveness. Typically, these inserts are engineered with multiple cutting edges, which allows for extended usage before the need for replacement. The multi-edged design ensures that as one edge wears down, another is ready to take over, providing consistent cutting performance. This rotational feature not only extends the lifespan of the inserts but also enhances the overall efficiency of the planing process.

Another noteworthy aspect of carbide planer inserts is their compatibility with various planer machines. Whether used in a stationary thickness planer or a portable planer, these inserts can be easily mounted and adjusted to fit different models and brands. The standardization of insert dimensions and mounting configurations simplifies the process of switching between different tools or replacing worn inserts, reducing downtime and maintaining productivity.

Advanced coating technologies further enhance the performance of carbide planer inserts. Coatings such as titanium nitride or titanium carbonitride are applied to the surface of the inserts to improve their hardness and reduce friction. These coatings not only extend the life of the inserts but also enhance their resistance to thermal and chemical damage, ensuring consistent performance even under the most challenging conditions.

The economic benefits of using the best carbide planer inserts are substantial. While the initial investment may be higher compared to traditional blades, the long-term savings are significant. The durability and extended cutting life of carbide inserts translate into fewer replacements and reduced maintenance costs. Additionally, the improved cutting efficiency and quality can lead to faster project completion and fewer defects, which translates into increased profitability for woodworking professionals.

In woodworking, precision is paramount, especially when creating intricate designs or high-quality finishes. Carbide planer inserts excel in this regard, providing the sharpness and consistency needed to achieve precise dimensions and smooth surfaces. For industries such as cabinetry, furniture making, and architectural woodworking, the reliability of carbide planer inserts is a key factor in meeting stringent quality standards and customer expectations.

The ongoing advancements in carbide insert technology continue to push the boundaries of what's possible in woodworking. Innovations in insert design, coating materials, and manufacturing processes are constantly being explored to enhance performance and address the evolving needs of the industry. These developments ensure that carbide planer inserts remain at the forefront of cutting technology, offering woodworking professionals the tools they need to excel in their craft.

In essence, the best carbide planer inserts represent a convergence of durability, precision, and efficiency. Their superior material properties, advanced design features, and compatibility with various machines make them a vital component in achieving exceptional woodworking results. As the industry continues to evolve, these inserts will undoubtedly play a crucial role in shaping the future of woodworking, offering professionals the reliability and performance needed to bring their creative visions to life.